What is AC Balance in TIG Welding? (Correct Settings)

One of the many confusing features of TIG welding is AC balance. Setting the balance correctly is essential because it’s one of the advantages of modern TIG machines. Let’s start with an overview.

AC balance is a feature of inverter AC/DC TIG welders used for aluminum welding. Balance manipulates the arc by controlling how much time the two polarities DC+ and DC- last for each AC cycle. With AC balance, you increase the pros and avoid the cons that each polarity has on aluminum.

AC balance has become mainstream because it greatly improves aluminum welding. After reading this article you will know how it works, the benefits, and what settings are the best for shiny and strong beads.

Table of Contents

- Why do you need AC for aluminum?

- Why do you use AC balance in TIG welding?

- Advantages of AC balance for aluminum

- What happens if the cleaning action (EP) is too low?

- What happens if the cleaning action (EP) is too high?

- How to set the AC balance on a TIG welder?

- When to increase the cleaning action (EP)?

- What to look for when setting the balance

- Conclusion

Why do you need AC for aluminum?

When oxygen contacts clean aluminum, the two elements form an oxide that introduces great difficulties for TIG welding:

- The aluminum oxide acts as a heat barrier because it has a high melting point of 3,762 °F (2,072 °C), preventing fusion.

- The oxide is not a metal and acts as an electrical barrier, preventing a smooth arc start.

- It creates sparks and spatter that stick to the tungsten electrode.

- It contains moisture that creates porosity in the bead.

- It acts as an impurity, making the bead brittle.

- The final bead is uneven, gray, and ugly.

Even if you clean the surface, a new oxidized layer will form rapidly. With TIG, even a thin layer creates problems.

To solve the aluminum oxide problem, you use a TIG machine that delivers alternating current (AC).

AC alternates between the two polarities, direct current negative (DC-) and positive (DC+), many times per second. The DC- polarity removes the oxidation, but only when it’s on the workpiece side.

Why do you use AC balance in TIG welding?

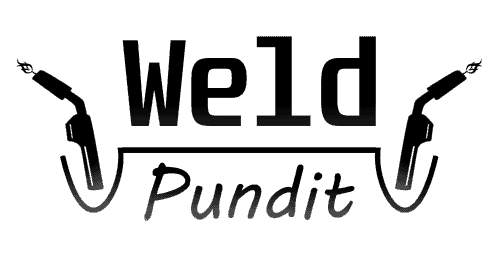

Most TIG welders are DC only, meaning the welding current always travels in one direction:

- When the torch’s polarity is DC-, we call it electrode negative (EN). Current travels from the torch towards the DC+ workpiece. This is the standard connection for DC TIG welding, but it cannot remove the aluminum oxide.

- When the torch’s polarity is DC+, we call it electrode positive (EP). Current travels from the DC- workpiece towards the torch. This connection can remove the aluminum oxide, but melts the tungsten’s tip.

Transformer AC TIG welders split the polarities into two equal time intervals. This has disadvantages:

- A 50% electrode positive (EP) time is more than enough to clean the oxide. A large part of the amperage overheats the tungsten, instead of being used for penetration.

- A 50% electrode negative (EN) time penetrates the metal, but doesn’t use as much of the set amperage as it could.

Inverter welding machines have high-tech components to manipulate the current and deliver it with improved characteristics. One of the improvements is the AC balance.

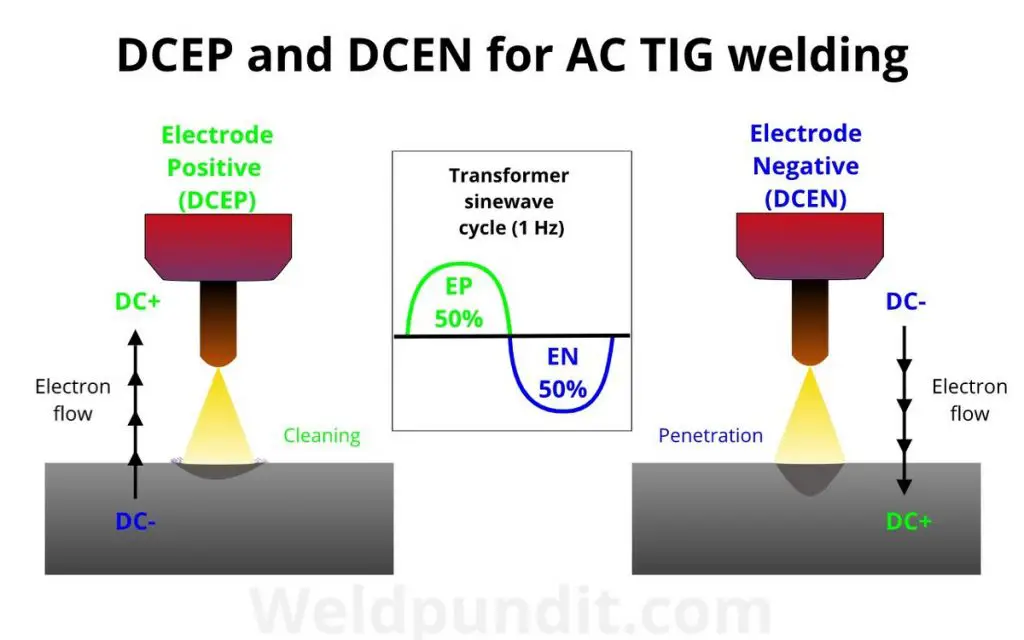

In TIG welding, you use AC balance to change the balance between the EN and EP portions of the AC cycle. You set a longer interval for the EN polarity, but a shorter one for EP.

This way you remove the aluminum oxide without melting the tungsten and achieve longer penetration time and lower energy consumption.

In other words, you increase the penetration time (EN) and you decrease the cleaning time (EP) or cleaning action.

The balance is always a percentage, when you change one polarity the other one automatically adjusts to the difference.

Advantages of AC balance for aluminum

With the balance feature, you use only the necessary energy for cleaning action. This way you achieve higher productivity and lower costs. In more detail:

- The arc digs deeper for improved penetration.

- You can weld at a faster traveling speed.

- You can use a slightly reduced amperage.

- You prolong the electrode’s life.

- Can use thinner electrode sizes with sharper tips.

- The final bead looks great and in most cases, it doesn’t need manual improvement.

However, if you don’t set the correct balance value, you can end up with numerous problems. Let’s see both scenarios.

What happens if the cleaning action (EP) is too low?

If you set a cleaning action (EP) that’s too low, the current cannot thoroughly remove the oxidation:

- The puddle will take time to form.

- The remaining oxides will contaminate the tungsten, making the arc erratic and unfocused.

- The puddle will look constricted and uneven.

- The puddle won’t wet out well.

- The filler rod won’t melt and flow into the puddle smoothly.

- On the molten metal, you will see floating dark particles.

- There is a chance that the workpiece will not melt properly, resulting in lack of fusion in various areas.

- The final bead will look dull and gray with porosity problems.

- Finally, the bead with not be as ductile (elastic) as it could be. Lower ductility means the bead will be more brittle and crack-sensitive. This is vital for critical welds that need full strength.

What happens if the cleaning action (EP) is too high?

If you set a cleaning action (EP) that’s too high, most of the bead will be clean and shiny, but:

- At some point, the tungsten will overheat and start to ball back unevenly. This will make the arc erratic.

- An erratic and unfocused arc will not stay on the desired path, resulting in a wider and uneven bead.

- The wandering arc can create porosity and reduced depth of fusion.

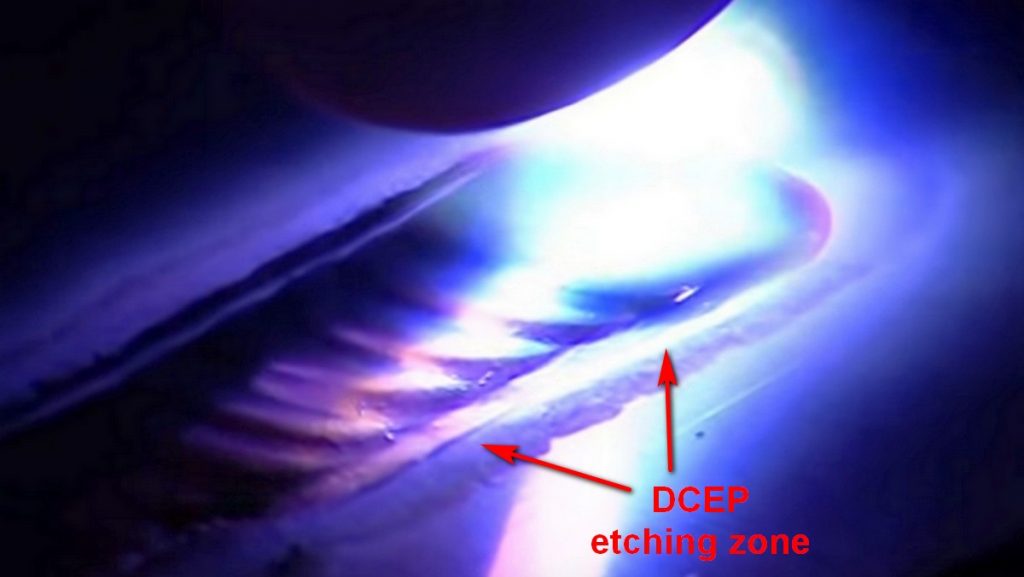

- The cleaning effect next to the bead (frost zone) will be very wide.

How to set the AC balance on a TIG welder?

While wrong balance settings can give detrimental results, setting the correct values is not hard.

You set the AC balance value on your TIG welder just enough to get satisfactory cleaning action, depending on the oxide thickness. Most often, a 70% electrode negative (EN) and a 30% electrode positive (EP) are suitable for most aluminum jobs.

There is no need to clean beyond what’s needed to get a shiny puddle. The lowest possible cleaning action will:

- Save the tungsten tip from balling and contamination.

- Offer deeper penetration.

- Create a narrower frost area next to the bead.

- Somewhat lower the amperage and the energy cost.

Most TIG welders have a balance range from 10% to 90%, They default the settings to high EN values, for example, 75% EN and 25% EP. These settings offer enough cleaning action if you:

- Remove the oxide without leaving residue.

- Do not leave the clean joint exposed for many hours.

- Weld tee and lap joints because it’s easier for the arc to cover the joint’s area.

- Ensure the bead has proper shielding gas protection.

If you follow the previous conditions and weld quickly, you can set an 80% EN and 20% EP. However, a lower cleaning action cannot prevent oxidation defects for most jobs.

Next to the bead, there is an area where the metal is free from oxide, and after that an area where it’s partially removed. We call this etching or frost area. The width it has is a good indication of excessive cleaning action.

If the etching area looks too wide, you can reduce the cleaning action, as long as the bead stays clean and shiny.

When to increase the cleaning action (EP)?

Setting up the perfect conditions isn’t always possible or practical. Let’s see when you can use a higher cleaning action to save time and increase your productivity:

- After cleaning the joint, a new oxide starts forming. The longer the joint is exposed to the air, the thicker the oxide layer gets. Often you cannot weld immediately after cleaning. Since the new oxide is quite thin, you can set a 70% EN – 30% EP balance. This setting is the most commonly used.

- If the joint was exposed for a longer time and slightly looks dull, you can set a higher EP balance, for example, 35-40% to get a clean puddle. However, with an EP value above 40%, it would be very difficult to avoid damaging the tungsten’s tip. High cleaning action is suitable for short beads, so you can stop before the tungsten overheats.

- You can also use high EP settings for brand-new aluminum without removing the oxidation. Brand-new aluminum is clean and has a thin oxide layer that the cleaning action can remove.

- You can also do that when you have oxide residues you cannot remove after cleaning the joint.

If you weld critical joints, you should perfectly remove the oxidation and follow the proper safety practices. It’s the only way to get a joint with the best strength and ductility.

Other situations when you can increase the cleaning action are:

- Butt joints and even more outside corner joints need higher cleaning action because the arc cannot cover the larger surface.

- When you don’t have perfect argon gas coverage. For example, you weld out of position, a complex joint, etc. When aluminum is hot, the oxide forms superfast.

- Welding cast aluminum is another example when increased cleaning action helps. Many castings may contain trapped air or oil. Those are sources of oxygen that rapidly forms the oxide as you weld.

- You can also increase the EP when you weld thin aluminum. It’s a tricky way to put less heat into the workpiece if you cannot use other ways.

Remember that a higher EP balance needs a thicker tungsten tip to keep a smooth and focused arc.

What to look for when setting the balance

One important thing to mention is that not all manufacturers use the same indication for the balance percentage:

- Most manufacturers prioritize the EN when you set the balance. For example, Miller, Lincoln, and HTP. On the welder’s controls, a value of 70 means 70% EN and 30% EP.

- Other manufacturers prefer showing the EP, for example, Everlast and Thermal Arc.

A quick look at the manual will tell you which polarity your welder sets. If you are in doubt, you can set a 70% value and run a short bead to check if the tungsten overheats or not.

Remember that the balance feature is only meaningful and accessible after you selected the AC welding mode. You don’t use it for DC welding.

Conclusion

Inverter AC TIG welders can control each polarity independently to make your work easier and more productive.

One way is the balance feature, the percentage of EN and the percentage of EP per AC cycle.

You set how much cleaning action you believe is necessary considering the present work. A balance of 30% cleaning action (EP) is enough for most jobs.

The most common mistake welders make with AC balance is using a high setting that damages the tungsten.

AC balance is very helpful, but you can weld without it. If you have an old AC TIG welder, you can use DC+ to intentionally ball back a pure tungsten electrode and then weld aluminum with AC.

Weldpundit articles

What Is AC Frequency in Tig Welding?