How to Store Stick Electrodes: With Tips for Home Welders

When storing stick welding electrodes, good practices can make a big difference in how long they stay in reliable condition and offer the best possible welds.

In this article, you can learn about rod storage and tips about how you can store them at home.

Table of Contents

- Can stick welding rods go bad?

- What is the shelf-life of a welding rod package?

- What welding electrodes are sensitive to moisture?

- How can you store rods that aren’t moisture-sensitive?

- How to store welding rods at home?

- Conclusion

Can stick welding rods go bad?

Stick welding rods can go bad if you don’t follow proper storage conditions or handle stick electrodes without care. Their life expectancy gets shorter with time and can become unusable when the flux covering shows signs of decay.

Stick welding rods have a sensitive and brittle flux coating. The flux material is necessary and has many functions, such as:

- Generates shielding gases to protect the molten metals from the air.

- Generates slag material that cleans and insulates the weld metal.

- Stabilize the arc and direct it to the desired path.

- Provides additional elements to improve the weld metal.

With poor handling, you can crack the flux and receive faulty welds as a result. Furthermore, if the damage is too much and small pieces chip off, the arc becomes too unusable, and you will throw the rods away.

Moreover, the flux material is sensitive to moisture. Exposed rods will absorb humidity from the air. Depending on the flux type, moisture can lower the rods’ quality to unusable levels.

Humidity isn’t the only pollutant. Dust, oil, and grease must not come in contact with the flux either. These pollutants will interfere with the shielding gases and find their way into the weld metal.

As a result, you will end up with several welding defects such as porosity or hydrogen embrittlement.

What is the shelf-life of a welding rod package?

The self-life of a welding rod package is the storage timespan from the production date until the time that the electrodes can deliver high-quality professional welds.

The packages’ self-life period depends on their packing type, the storing conditions, and how sensitive flux the electrodes have.

Types of stick electrode packages:

- Paper packages that do not protect the rods well from moisture or mechanical damage.

- Plastic packages have much lower moisture absorption.

- Airtight sealed canisters and vacuum-sealed bags are the best types. These types are the only suitable packages to store hydrogen-sensitive rods such as the E7018 the right way.

Recommended storage conditions

The correct rod packaging storage conditions are essential for critical and high-quality professional work.

Furthermore, if you weld at home, you want to store the rods correctly if you want them to perform as intended.

As long as you store the rods according to the manufacturer’s recommendations, they can keep their desired working condition.

Basic electrode packaging storage recommendations are:

- Always keep the packages indoors and protect them from water damage.

- Keep them at a temperature between 40-120°F (4-48°C).

- The temperature must not fluctuate at high rates.

- Keep them at low humidity of 50%.

- Avoid high-temperature variations to avoid concentrating moisture on their surface.

If the above conditions are met, rods in sealed canisters and vacuum-sealed bags keep their desired characteristic at least for 5 years. Other package types cannot guarantee it because they are easy to break and let moisture inside.

What welding electrodes are sensitive to moisture?

The most moisture-sensitive welding electrodes are the low-hydrogen electrodes such as the E7018. If these electrodes absorb moisture from the air, even for a short time, they will not provide safe welds for critical work.

Manufacturers design low-hydrogen rods to weld steel sensitive to hydrogen embrittlement. For example, medium-carbon, low-alloy, and already hardened steel.

Hydrogen embrittlement means that hydrogen trapped in the weld and the surrounding area can cause cracking. But only if the metal takes stress, either internal from shrinkage or external from the weldment’s service conditions.

That happens because the extreme heat of the arc breaks down the absorbed moisture into hydrogen and oxygen that end up in the weld.

While hydrogen embrittlement is the worse welding defect, other defects and poor arc characteristics caused by improper electrode storage are:

- Hard arc striking.

- Unstable arc during the weld.

- Frequent or even continuous porosity.

- Nonmetallic inclusions caused by excessive oxygen.

- Extensive spatter.

- Difficult to remove slag.

- When moisture concentrates in the flux unevenly, you will have uneven rod consumption (fingernail). Fingernailing will force the arc to point to the weaker side.

You should use low-hydrogen rods within a narrow timespan after opening their packaging. Exposed low-hydrogen rods must be rebaked in welding rod ovens.

The usage periods of moisture-sensitive rods are shown in the following table.

| Low-hydrogen electrode | hours |

|---|---|

| E7018 | 4 |

| E7018R | 9 |

| E8018 | 2 |

| E9018 | 1 |

| E10018, E11018 | 1/2 |

Other electrodes sensitive to moisture

All welding electrodes that don’t weld mild steel have flux coverings sensitive to moisture. For example:

- Stainless steel rods must be handled like low hydrogen rods, especially the EXXX-15 type.

- Cast iron rods are also very sensitive to moisture contamination. Since they are very expensive, you should keep them protected.

- Aluminum rods are even more sensitive than the previous rods. Their flux will absorb moisture at fast rates and form hydrated oxides. As a result, aluminum rods will give terrible welds with extreme porosity.

If you leave these rods unprotected, their flux will decay at fast rates, and you cannot recondition them to their original condition.

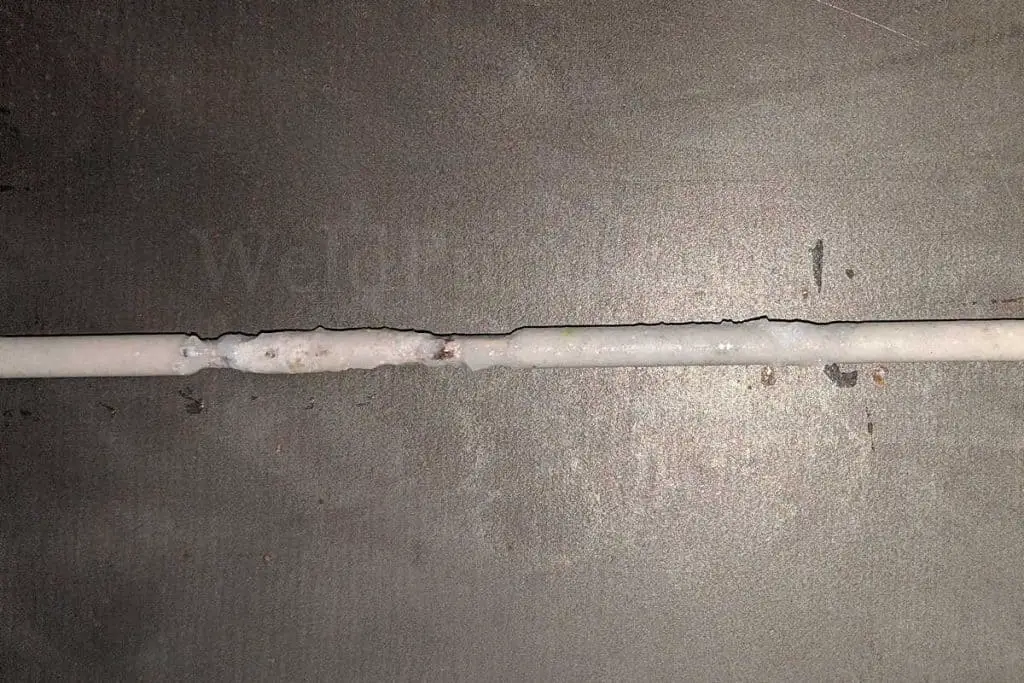

As an extreme example, take a look at the following E4043 aluminum rod, which I left outside for a couple of days.

Manufacturers always supply these moisture-sensitive rods in airtight sealed containers or heavy-duty vacuum bags, which provide excellent protection.

How can you store moisture-sensitive electrodes?

After opening their package, the only correct way to store moisture-sensitive electrodes is to put them in a welding electrode oven. No other solution is safe enough for critical or professional work when using these rods.

When you open a low-hydrogen rod package, you must use the rods within a specific period or store them in a rod oven to prevent moisture absorption. This way, you won’t have to rebake them. Rebaking requires heavy-duty rod ovens.

The temperatures to store rods in ovens are specific:

- If the temperature is lower, the rods will not be 100% safe from absorbing moisture.

- Store the rods at higher temperatures, and the flux will deteriorate. As a result, you can’t do any critical work with them.

The following chart is a general example of storing temperatures for moisture-sensitive rods. Every manufacturer mentions their own precise temperatures for each rod they produce.

| Electrode type | Storage oven temperature |

|---|---|

| Low-hydrogen Exx15, Exx16, Exx18 | 250°F-300°F (120° to 150°C) |

| Stainless steel EXXX-15 | 225°-260°F (105° to 125°C) |

| Cast iron nickel rods | 215°-230°F (100° to 110°C) |

Weldpundit has a more in-depth article on welding rod ovens, rebaking, and temperatures.

How can you store rods that aren’t moisture-sensitive?

When storing welding rods that don’t have low-hydrogen flux, things are much simpler.

Cellulosic rods

Cellulosic rods such as the E6010 and the E6011 are the easiest rods to store.

It is normal for cellulosic flux to have at least 4% moisture in their flux.

If you store cellulosic rods in high temperatures, they will dry up. As a result, their flux will deteriorate, precisely the opposite of low hydrogen rods.

In the original package, cellulosic rods are stored at 40-120 °F (4-48 °C) with 50-70% humidity.

After opening the package, keep the rods in sealed plastic tubes. They will protect the rods enough from physical damage and keep their moisture content.

Rutile rods

Rutile rods such as the E6013 and the E7014 can absorb moisture from the air if left exposed for a long time.

However, rutile rods are not as sensitive as low-hydrogen rods. They work great, except if they are meant for critical work, which is rare.

In the original package, rutile rods are stored at 40-120°F (4-48°C) with 50-70% humidity.

After opening the package, store rutile rods in rod ovens if they will weld something with demanding service conditions. The storage temperatures for rutile rods are relatively low, at 100-130 °F (38 to 55 °C).

For normal welding, store rutile rods like cellulose rods in their own sealed containers.

How to store welding rods at home?

For home welding, rod storage is not strict except if you are welding something critical, for example, a trailer. Ensure you store the rods indoors at a stable temperature, low humidity, and away from water.

If the rods came in an airtight package, you can continue keeping them in it. If they came in a paper or plastic package, you can put them in rod containers or seal them in your own vacuum bags.

What is a welding rod storage container?

A welding rod storage container is a simple solution for storing rods. They are affordable, and you can buy a couple of them at a local hardware store. You can also make your own electrode containers from plastic tubing.

Electrode containers are easy to make from cheap PVC tubes. You can also weld metallic containers as a home project, but they will be heavy. Ensure that they are airtight.

Furthermore, if you have some kind of airtight box that is big enough for the rods, you can use it as a welding container.

If you place some silica bags in the container, they will hold the rods extra dry.

Can you use a vacuum sealer machine to store electrodes?

You can use a vacuum sealer machine to store welding electrodes, and it is a great solution if you want to store them for an extended time in moisture-heavy environments.

You can put the rods in plastic or, even better, an aluminized bag and seal them with a home vacuum sealer. The sealer will absorb all the air from the bag, ensuring no moisture will affect the rods.

The downside is that if these bags are accidentally struck, the rod flux will not be protected.

Remember that you should never store different types of rods in the same container or bag. For example, E7018 rods with E6010 rods. All of them will go bad.

If you want to weld critical work with low-hydrogen rods, you need a proper rod oven.

If you use low-hydrogen rods for non-critical welding, you can store them like rutile rods but in their separate container.

Of course, there is no reason to buy these rods for common welding. There are efficient, cheaper, and easier-to-use rods for home welding.

Conclusion

Welding rods can go bad. Correct storage and handling are essential to preserve life expectancy and performance.

Low-hydrogen rods are very sensitive to moisture. For critical work, you must store them in rod ovens after you open the package. For non-critical work, keep them in airtight containers.

Non moisture-sensitive rods are easy to store by keeping them away from excess moisture. With careful storage, you can preserve them for years without turning bad and with good results for home projects.