Stick Welding Rod AWS Classification (Steel, Cast Iron, etc.)

When you pick up a stick welding electrode, you see a designation printed on it, for instance, E7014. Each letter or number has much to say about the rod’s nature.

In this article, you will learn what each designation means for the most common rods.

Table of Contents

- What is an AWS stick welding electrode classification?

- Low-carbon steel rods for carbon steel

- Low-Hydrogen rod suffixes indicate heavy-duty work

- Low-alloy rods for alloyed steels

- Stainless steel rods

- Cast iron rods

- Aluminum rods

- Copper rods

- Nickel rods

- Conclusion

What is an AWS stick welding electrode classification?

The American Welding Society (AWS) welding electrode classification system helps to designate the electrodes according to their chemical composition and/or mechanical properties. It helps you to know the electrode’s capabilities and uses.

Low-carbon steel rods for carbon steel

The common ferrous metals are low-carbon steels such as the A36 grade. You weld these metals with familiar rods such as the E6010, E6013, and E7018.

Their designation includes the tensile strength, the welding positions, and the current type they support.

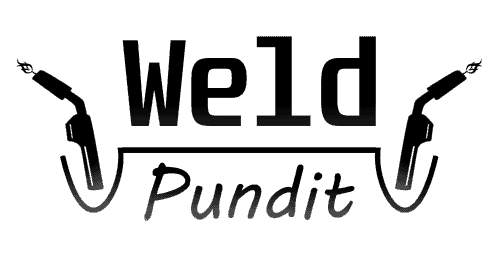

At first glance, their designation looks puzzling: EXX(X) YY. It starts with the prefix letter E, indicating you have an electrode covered with flux material and not a simple filler metal.

The first two or three digits (XXX) indicate the minimum tensile strength of the weld metal. Tensile strength is the force a metal can withstand when pulled apart before it breaks. It’s measured in kilopounds per square inch (ksi). Each kilo is a thousand pounds per square inch (psi).

Low-carbon steel rods have a typical strength of 60ksi (60,000psi) or 70ksi. In reality, they are stronger by at least 10%. This way, they cover the stronger grades of low-carbon steels.

The second from last digit refers to the welding positions the rod supports:

- EXX1X rods weld in all positions: flat, horizontal, vertical, and overhead. However, many rods have difficulty welding vertically down.

- EXX2X rods weld great in the flat position, but only fillet welds in the horizontal position. They don’t weld in the vertical or overhead position.

- EXX3X rods are for the flat position only, but they are obsolete.

- EXX4X indicates excellent results in the vertical down position. They are rare to find.

Finally, the last digit ranges from 0 to 8 and, in combination with the previous one, indicates a lot about:

- The flux composition

- The arc’s penetration, and

- The current types the rod supports.

The following table shows the most common rod designations for low-carbon steel. You can see the two last designation digits, the flux chemistry, the current type, and their arc strength.

| Designation | Flux material | Current Type | Penetration |

|---|---|---|---|

| EXX10 | Cellulose-Sodium | DC+ | DEEP |

| EXX11 | Cellulose-Potassium | AC & DC+ | DEEP |

| EXX12 | Rutile-Sodium | AC & DC- | MEDIUM |

| EXX13 | Rutile-Potassium | AC & DC | LIGHT |

| EXX14 | Rutile-Iron powder | AC & DC | LIGHT |

| EXX15 | Low Hydrogen-Sodium | DC+ | MEDIUM |

| EXX16 | Low Hydrogen-Potassium | AC & DC+ | MEDIUM |

| EXX18 | Low Hydrogen-Iron powder | AC & DC+ | MEDIUM |

| EXX20 | Iron Oxide-Sodium | AC & DC | MEDIUM |

| EXX24 | Rutile-High iron powder | AC & DC | LIGHT |

| EXX27 | High iron Oxide-Iron powder | AC & DC | MEDIUM |

| EXX28 | Low Hydrogen-High iron powder | AC & DC+ | MEDIUM |

| EXX48 | Low Hydrogen-Iron powder | AC & DC+ | MEDIUM |

Now let’s see as an example the designation of the popular E6010 rod:

- E – it is a stick welding electrode.

- 60 – it has at least 60ksi tensile strength.

- 1 – it welds in all positions.

- 0 – it welds only with DC+.

- 13 – the flux has a high amount of rutile mineral and a low amount of iron powder.

Another example is the E7024 rod:

- E – it is a stick welding electrode.

- 70 – it has at least 70ksi tensile strength.

- 2 – it welds butt and fillet welds in the flat position, but only fillet welds in the horizontal position.

- 4 – it welds with all current types.

- 24 – the flux has high amounts of rutile mineral and high amounts of iron powder.

Low-Hydrogen rod suffixes indicate heavy-duty work

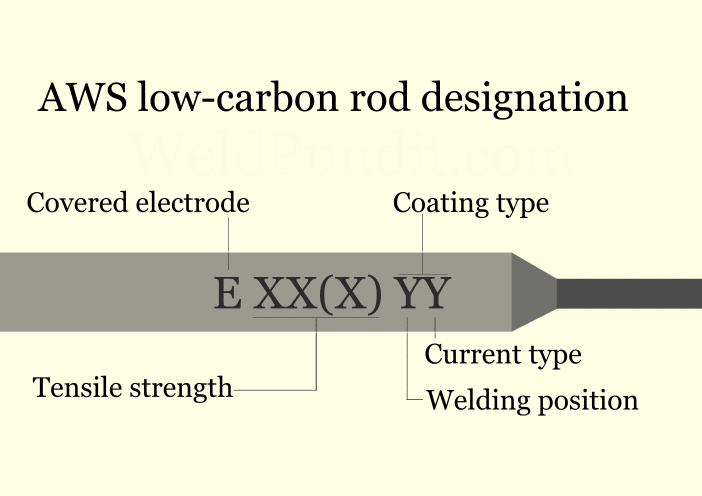

Often, critical welds need rods with extra low-hydrogen content to avoid the cold cracking risk. For this, many low-hydrogen rods such as the EXXX5, EXXX6, and EXXX8 have suffixes that indicate their diffusible hydrogen content.

Furthermore, the suffix may indicate added moisture resistance. This extends their time before they are deemed unsafe for joints with demanding service conditions.

Let’s see what the suffix -Hz R means:

- Hz. The letter z indicates the maximum diffusible hydrogen limit in milliliters per 100 grams of weld metal:

- 16mL/100g

- 8mL/100g and

- 4mL/100g

- R offers higher resistance to moisture absorption when the flux is exposed to the environment.

For example, the E7018-H4R rod:

- H4 means it contains a maximum of 4ml of diffusible hydrogen per 100gr of weld metal.

- R means that the flux is resistant to moisture absorption for 9 hours instead of the 4 hours a typical basic rod has (at 80 °F (27 °C) and 80% relative humidity)

Low-alloy rods for alloyed steels

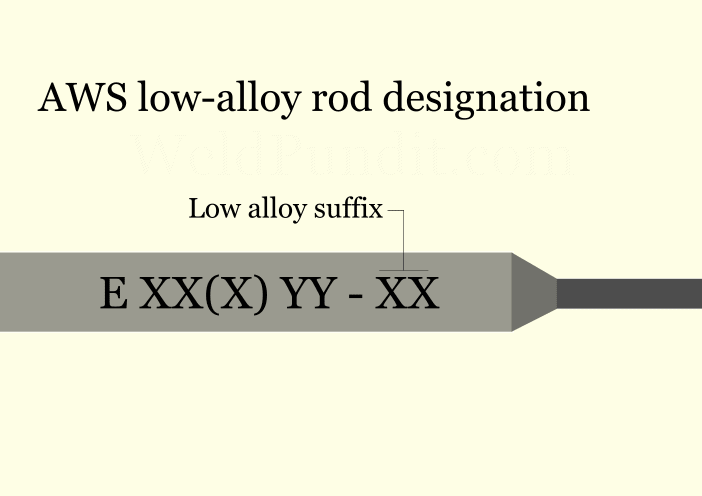

Low-alloy rods are low-hydrogen rods but with added alloying elements in their flux. The added elements offer welds with higher strength, heat, cold or corrosion resistance, and so on.

Their designations are quite similar to low-hydrogen rods, but with:

- A variety of tensile strengths from 70ksi up to 120ksi.

- Additional suffixes that indicate the added alloying elements, for example, E10018-A1.

Low-alloy rod suffixes

There are many suffixes. Here are the most common ones along with their alloying elements.

1. Molybdenum suffix:

- A1 has 0.5% Molybdenum (Mo) that offers high strength at high temperatures.

2. Chromium-Molybdenum suffixes:

- B1 has 0.5% Mo and 0.5% Chromium (Cr) that add corrosion resistance.

- B2 has 1.25% Cr and 0.5% Mo.

- B3 has 2.25% Cr and 1% Mo.

- B5 has 0.5% Cr and 1% Mo.

3. Nickel suffixes:

- C1 has 2.5% Nickel (Ni) that offers high toughness at cold temperatures.

- C2 has 3.5% Ni.

- C3 has 1% Ni, 0.15% Cr, and 0.35% Mo.

4. Manganese-Molybdenum suffixes:

- D1 has 0.25% Mo and 1.75% Manganese (Mn) that increase strength and cracking resistance.

- D2 has 0.45% Mo and 1.75% Mn.

5. Other low-alloy suffixes:

- G can have 0.5% Ni, 0.3% Cr, 0.2% Mo,1% Mn, and 0.1% Vanadium (V). Only one of these has to meet the requirement. Manufacturers make rods with a G suffix for specific jobs that other electrodes cannot cover. Rods with this suffix are always different.

- L attaches to previous suffixes and indicates lower carbon, for instance, -B2L.

- M indicates special military requirements. In most cases, it is similar to E7018-1H4R, but better.

- A numerical suffix –1 may follow the previous prefixes. It indicates improved toughness and ductility (elasticity) at very low temperatures.

An example of a low-alloy rod is E10018-A1 used for carbon-molybdenum low-alloy steels. The A1 suffix means the flux covering has an added 0.5% molybdenum for higher strength at high temperatures.

Stainless steel rods

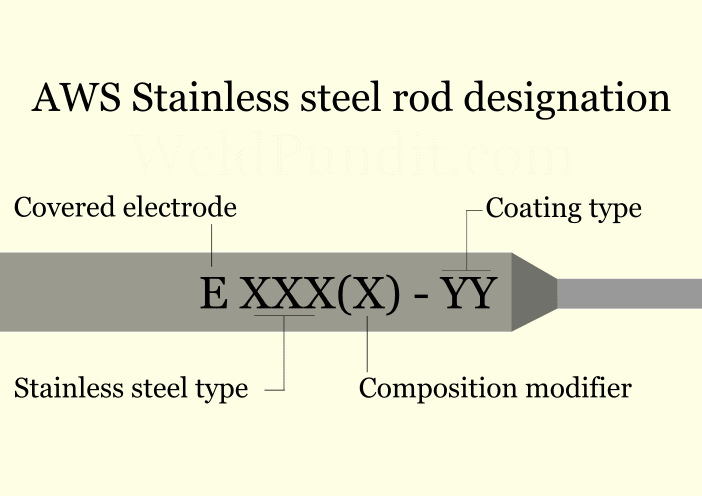

Stainless steel rods have a letter-based designation, E-XXX(X)-YY:

- E indicates a covered electrode.

- After that comes a three-digit indication of the weld metal’s chemical composition.

- Next, an optional letter indicates changes to the chemical composition. For example, L indicates a lower carbon amount, H indicates the opposite, a higher carbon.

- As a suffix, there are two digits that indicate the flux composition, the welding positions, and the current type.

For example, the E308L-15 rod:

- 308 – the weld metal is the AISI 308 stainless steel low-carbon grade with 20% chrome, and 10% nickel.

- L – the weld metal contains less carbon (0.03%) than the typical 308 (0.08%) grade.

- 15 – the rod has a basic flux covering. The rod can weld at all positions with DCEP (DC+) current.

| Designation | Flux | Current Type | Weld Positions |

|---|---|---|---|

| EXXX-15 | Basic | DCEP | All |

| EXXX-16 | Rutile | AC & DCEP | Flat and horizontal fillets |

| EXXX-17 | Rutile- Acid | AC & DCEP | Flat and horizontal fillets |

Cast iron rods

Cast iron rods have a letter-based designation, E-XX(XX)-CI-X:

- They start with the prefix E indicating a covered electrode.

- After that, letters indicate the primary elements of the rod.

- The first suffix indicates that these are cast iron (CI) rods and not typical nickel rods. The two exceptions that don’t have this suffix are the ENiCu-A and the ENiCu-B rods.

- An optional second suffix indicates the subclassification of the rod. This happens when there are different compositional limits of alloy elements. Two letters are used for this, A and B.

For example, the ENiFe-CI-A rod:

- Ni – indicates a high percentage of nickel (55%).

- Fe – indicates a high percentage of iron (45%).

- CI – it is a cast iron rod.

- A – the rod has a higher aluminum content than normal.

Aluminum rods

Aluminum rods have a simple designation, E-XXXX:

- E indicates a covered electrode.

- The next four numbers indicate the composition of the core wire, according to the Aluminum Association classification of aluminum alloys.

For example, the E4043 rod:

- 4043 indicates an AL4043 aluminum alloy with a high silicon amount as the primary alloying element.

Copper rods

Copper rods have a letter-based designation, ECuXX-XX:

- E indicates a covered electrode.

- Cu that it has a copper alloy core wire.

- The next two letters indicate the primary alloying element.

- A suffix letter indicates the subclassification of the rod. This happens when there are different compositional limits of alloy elements. Three letters are used for this, A, B, and C.

- Finally, a number may indicate further subdivisions.

For example, the ECuAl-A2 rod:

- Cu – it is a rod for copper alloys.

- Al – aluminum is the primary alloying element.

- A2 – it has an additional 1.50% of iron.

Nickel rods

Nickel rods also have a letter-based designation, ENiXXXX-X:

- E indicates a covered electrode.

- Ni that it is a nickel rod.

- There may be one or two atomic symbols of the primary alloying elements.

- The suffix indicates subdivisions of the rod according to changes in alloying element amounts.

For example, the ENiCrFe-2 rod:

- Ni – it is a nickel rod.

- Cr – chromium is the primary alloying element.

- Fe – iron is the second alloying element.

- 2 – it has added molybdenum.

Conclusion

Stick electrode designations are necessary to know how to use them. However, the designations are hard to remember, especially if they have many suffixes.

You can also read this introductory article on stick welding electrodes that covers the basics.