Welding Helmet Fogging up? 10 Ways to Prevent It

The fogging of a welding mask can be aggravating. In this guide, you’ll learn what causes fogging and how to avoid it in 10 helpful ways.

What causes a welding helmet to fog up?

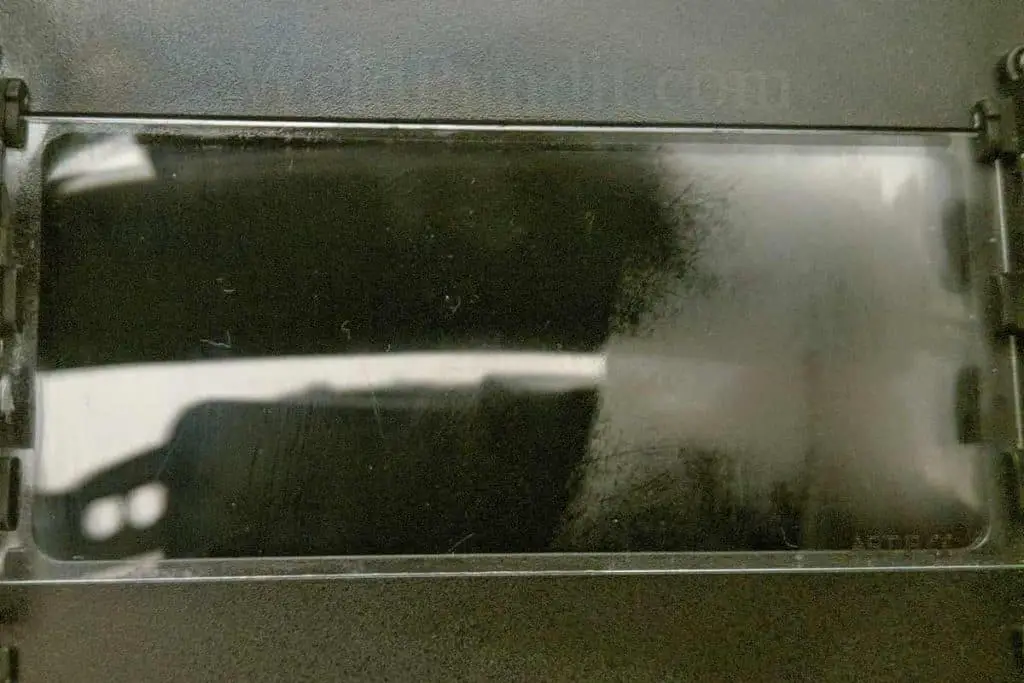

A welding helmet fogs up when hot moisture from your breath or sweat makes contact with the inside cover lens. The helmet’s temperature is lower than your breath or sweat, which forces the excess moisture to concentrate on the cover lens as numerous tiny droplets.

Fogging happens very fast and prevents your clear view of the puddle, causing mistakes, delays, and frustration.

The phenomenon of the air’s moisture transformation to water is called condensation (Wikipedia).

What worsens fogging?

The factors that make a welding helmet fog at higher rates are high temperature differences, high moisture levels, and the distance between your face and the cover lens.

Fogging worsens when the environment’s temperature is considerably low. The rate at which moisture converts to fogging increases as the temperature of the helmet decreases. That’s why fogging happens faster and is more persistent when welding in a cold environment, for example, outside in the winter.

If you work in a warm environment or put a lot of effort into your work, you will sweat heavily. Sweat in combination with your breath will result in high levers of moisture that will turn to fog. Even if the environment’s temperature is not very low.

The distance between your face and the cover lens is an important factor. The closer your face is to the cover lens, the stronger the moisture density and temperature are.

What is the best way to prevent fogging?

Before examining all the ways to prevent fogging, let’s mention the install-and-forget way to do it.

The best way to prevent your welding helmet from fogging is to permanently install an antifog film on the cover lens that also protects it from physical damage.

10 ways to prevent a welding helmet from fogging up

Let’s take a closer look at the antifog film and the other methods to prevent fogging up.

1. Install a permanent antifog film.

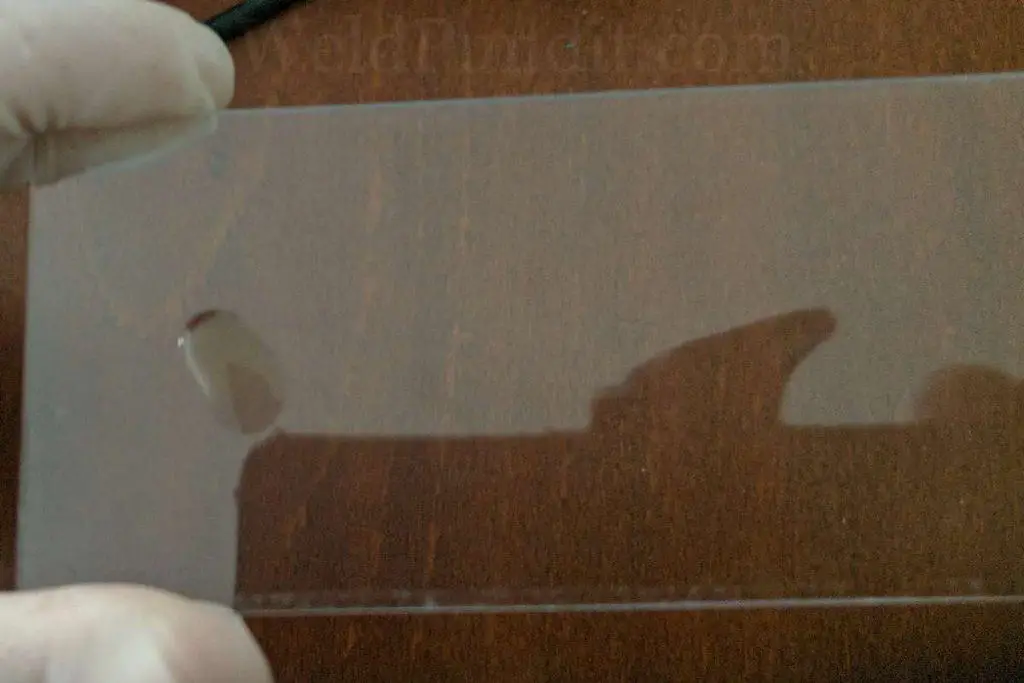

Antifog films are thin plastic sheets from polycarbonate or polyester material. These films are also called anti-condensation or anti-mist films. A permanently attached film is the most comfortable way to prevent fogging.

The only difficulty is finding a suitable film. A general-purpose film used for mirrors, windows, etc., that is thin, flexible, and totally transparent is good enough.

The advantages of antifog films are:

- They are very effective at preventing fogging even in harsh conditions.

- They are a permanent solution and last for a long time.

- The material is resistant to heat.

- They provide excellent visibility.

- They offer additional scratch resistance to the cover lens.

- There are no chemicals to evaporate during welding.

You permanently attach the antifog film to the exposed side of the inside cover lens. It is easy to install:

- Remove the helmet’s inside cover lens.

- Cut the film to fit the lens dimensions.

- Clean both sides of the lens with an alcohol-based cleaner to remove all dirt, even your fingerprints. Wearing single-use elastic gloves helps to prevent fingerprints.

- When the cover lens is completely dry, you apply the film.

2. Use commercial antifog products.

There are many antifog products such as sprays, gels, and wipes to use. Most of these products have average results and are temporary solutions. You might even need to reapply the product more than once.

When you buy such products, you must be certain they are antifog. Products that repel rain or water aren’t the same.

You can find such products online or at local stores that sell equipment for:

- Skiing.

- Scuba diving.

- Motorcycles.

- Paintball.

Each product has its own instructions to achieve the best results. You remove the cover lens first and apply the product to the external side only.

The best one from my experience is an antifog wipe for ski masks. These wipes are pretty effective, and at the same time, they clean the cover lens.

3. Apply home materials with antifog properties on the cover lens.

You can use many home materials as a cheap and quick way to create a thin anti-fog layer. Some suitable materials are:

- Liquid dish soap.

- Bar soap.

- Shampoo.

- Shaving gel or foam.

- Toothpaste but only in the form of a smooth gel.

I have used these materials several times, and they work fine for a short period.

Things to consider before you create an antifog layer with home materials:

- Rule number one: never apply these materials on the welding filter itself, but only on the inside cover lens that protects it.

- Apply only on the external side of the cover lens. The filter must never come into contact with any chemical substance.

- You must remove the cover lens from the helmet. If you got an auto-darkening helmet, any liquids that will find their way into the filter’s electronic mechanism will damage it and void the warranty. Also, you do not want liquids to fill the gaps in your helmet.

- Even if the manufacturer says that the cover lens is scratchproof, it will get scratched or blurred if you rub it often. Even slight damage to the cover lens will result in poor clarity or glare.

How to apply home materials on the cover lens

The procedure to create a protective antifog layer is simple and quick.

- First, remove the inside cover lens and clean both sides with an alcohol-based cleaner. Wearing single-use elastic gloves is helpful.

- When the surface is completely dry, apply the material of your choice in the lowest quantity, just enough to cover the surface.

- Use a clean, soft rug to buff the surface until there are no visible remains because they can distort your vision when welding. Do not use rough or dirty rags or heavily used wipes to prevent blurring the cover lens. An ordinary but clean wipe for glasses is ideal.

- Reinsert the cover lens back into the welding helmet. The ultra-thin remaining layer is enough to prevent fogging.

4. Keep your welding helmet warm.

As mentioned, fogging happens when there are temperature differences. If the helmet is way too cold, even a couple of exhalations will cause fogging.

Before you start welding, you can place your helmet close to a heating source to warm it up. You can place your helmet close to a strong lamp, a warm engine, a generator, etc.

When you take your helmet off, leave it close to the heat source to keep it warm until you weld again.

Welding helmets are resistant to heat up to a point, but you should be careful not to damage the helmet from excessive heat.

5. Adjust your welding helmet.

Another simple but effective trick that will help you against fogging is to set a longer distance between your face and the cover lens.

Many welders prefer a small distance to see the puddle better, but when the lens fogs up, you don’t have a choice but to increase the distance.

6. Control your breathing.

Controlling the way you exhale is a very effective way to prevent fogging.

It’s better to breathe through your nose. This way, the moisture levels are reduced, the temperature is lower, and the moisture is directed downwards.

If you can only breathe through your mouth, try to exhale downwards as much as possible.

7. Control your sweating.

If you sweat a lot, you are going to have a big problem with fogging. The excess moisture that evaporates in front of the cover lens is too much.

You can lower your sweating rate by wearing breathable clothes, having good ventilation, and avoiding strenuous work before using your helmet.

8. Position yourself to avoid fogging.

If possible, position yourself so that any breeze in the environment enters your helmet and dilutes your breath or sweat. A breeze can also clear any present fogging.

You can create a helpful breeze by opening a window or placing a low-speed fan at the proper angle.

9. Prevent fogging with a necklace fan.

In the market, there are cheap portable necklace fans you can place around your neck. These fans point upwards and blow a gentle breeze in front of your face.

This breeze is excellent to dilute your breath, keep your sweat at low levels, and clear present fogging.

10. Prevent fogging by attaching small fans to your welding helmet.

Another trick you can do is modify your helmet and install small-framed fans of low voltage (5V). The basic idea is that you drill holes big enough to fit the fans at each side of the helmet at your eyes’ height.

However, since you modify the helmet, it’s a good idea if it’s still under warranty.

Conclusion

A welding helmet fogs when you weld in a cold environment, or you release moisture from sweating and breathing.

The best solution is to install an antifog film on the inside cover lens. After that, you can use several commercial products or house materials to create a helpful but temporary antifog layer.

Other effective ways to prevent fogging are keeping your helmet warm, controlling your breathing, and preventing excessive sweating.

More Weldpundit articles